Introduction

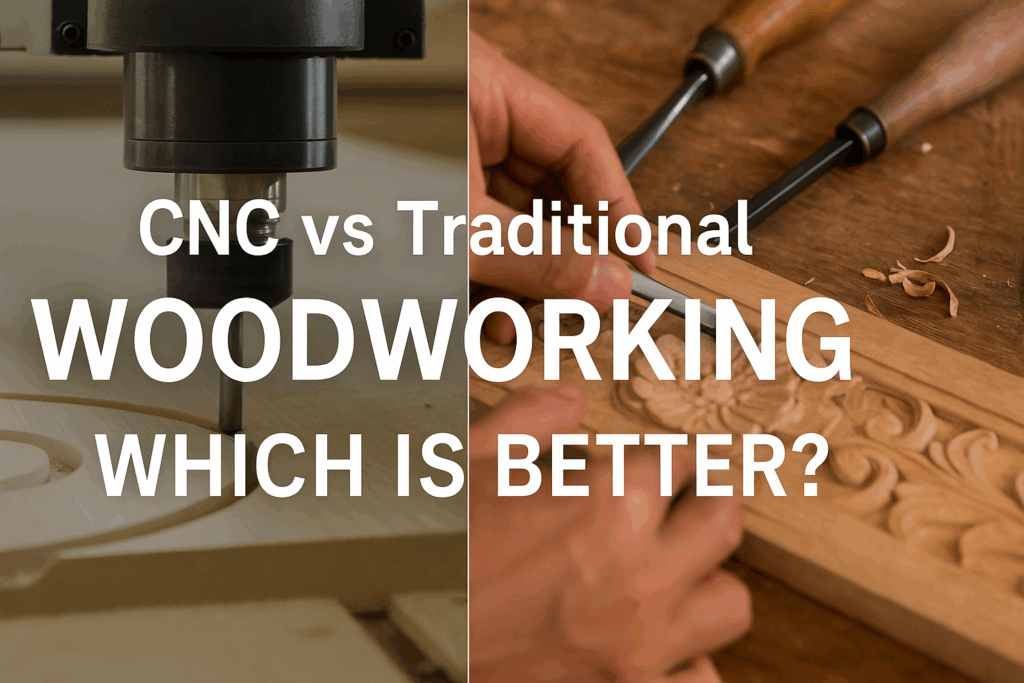

When it comes to interior woodworking in Ontario, homeowners and designers have more options than ever before. The emergence of CNC (Computer Numerical Control) technology has brought a high-tech twist to traditional woodworking methods, offering speed, precision, and scalability. But does that mean the age-old art of handcrafting furniture and décor is obsolete?

In this blog, we’ll compare CNC woodworking vs traditional woodworking, focusing on their pros, cons, and best applications in interior projects. Whether you’re furnishing a condo in downtown Toronto or renovating a cottage in Muskoka, this guide will help you choose the right approach.

What is CNC Woodworking?

CNC woodworking is a modern manufacturing process that uses computer-controlled machines to cut, shape, and carve wood. Designs are created using CAD (Computer-Aided Design) software and then sent to a CNC router or milling machine to produce the final piece.

Common CNC Applications in Interior Design:

- Geometric wall panels

- Custom kitchen cabinetry

- Intricate wooden signage

- Laser-cut shelving and partitions

CNC machines are valued for their precision, consistency, and speed, making them ideal for replicating designs on a large scale without sacrificing quality.

How Much Does a CNC Woodworking Interior Project Cost in Ontario? A Homeowner’s Guide

What is Traditional Woodworking?

Traditional woodworking involves manual tools and artisan skills to cut, shape, and assemble wood. Craftspeople often use chisels, hand saws, lathes, and planes—techniques that have been refined for generations.

Typical Interior Applications in Ontario Homes:

- Hand-carved staircases and banisters

- Vintage-style cabinetry and trims

- Custom hardwood furniture

- Decorative mouldings

The charm of traditional woodworking lies in its personal touch and uniqueness, making each piece feel like a work of art.

CNC vs Traditional Woodworking: Head-to-Head Comparison

| Feature | CNC Woodworking | Traditional Woodworking |

| Precision | Extremely accurate, computer-controlled | Dependent on craftsman’s skill |

| Speed | Fast once programmed | Slower due to manual labor |

| Customization | Excellent for digital designs and complex patterns | Ideal for organic, hand-shaped elements |

| Cost | Higher initial cost, but efficient in the long run | Lower upfront cost, but high labor cost |

| Skill Requirement | Requires knowledge of CAD/CAM and machine operation | Requires years of hands-on craftsmanship |

| Material Waste | Minimal due to exact cutting paths | Higher waste risk from human error |

Best Use Cases for Each Method

🛠 CNC Woodworking is Ideal For:

- Modern interiors in places like Mississauga condos or newly built homes in Ottawa.

- Mass-produced yet customized elements such as kitchen doors or paneling.

- Commercial interior design for retail or office spaces that need speed and scalability.

🪚 Traditional Woodworking is Ideal For:

- Restoration projects in historical Ontario homes or Victorian-era properties.

- Luxury furniture pieces that require artisan detail and uniqueness.

- Custom, one-off designs where human creativity outweighs machine precision.

The Hybrid Approach: Best of Both Worlds

Many woodworkers and interior designers in Ontario now use a hybrid method, combining the best of both worlds. For instance, CNC machines can quickly rough out a design, and then a craftsman can add hand-finished touches for detail and authenticity.

This blend allows for:

- Efficient production

- Cost-effectiveness

- High-end craftsmanship

Especially for custom home builders in areas like Oakville or Aurora, this approach strikes the perfect balance between tradition and innovation.

The Future of Custom Interiors: CNC Router Trends to Watch in Ontario

Final Verdict: Which is Better for Your Interior Project?

There is no one-size-fits-all answer. The right choice depends on your project goals, timeline, budget, and design vision.

- ✅ Choose CNC woodworking if you need high precision, faster turnaround, and scalable design.

- ✅ Choose traditional woodworking if you want handcrafted elegance, heritage appeal, and artisan value.

For homeowners across Ontario, blending both methods often provides the most flexibility and best results.

Conclusion

CNC and traditional woodworking each bring their own strengths to the table. Whether you’re revamping a modern loft in downtown Toronto or restoring a classic farmhouse in Guelph, the key is understanding what your project demands. While CNC offers speed and precision, traditional craftsmanship delivers timeless character and uniqueness.

At the end of the day, Ontario’s diverse interior design landscape benefits from both these powerful methods.

Need Help Choosing the Right Woodworking Method?

If you’re planning a custom interior project in Ontario and aren’t sure which method to go with, get in touch with our expert team. We specialize in both CNC and traditional woodworking and can guide you toward the best solution for your vision. 📞 Contact us today for a free consultation!

FAQ

Q: Is CNC woodworking more expensive than traditional methods?

A: Not always. CNC may have a higher upfront cost but can be more economical for bulk or repeated designs due to reduced labor and waste.

Q: Can traditional woodworking achieve the same detail as CNC?

A: Yes, especially for artistic or organic designs. However, CNC can outperform in complex geometrical patterns and consistency.

Q: Are there local woodworking shops in Ontario that offer both services?

A: Yes, many modern woodworking companies in Ontario now provide hybrid solutions combining CNC precision with traditional hand-finishing.